Green Manufacturing Hubs

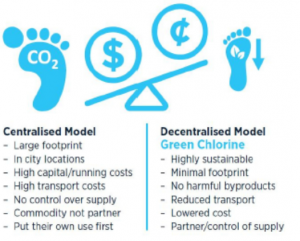

Grenof (a clean technology award winner) through its bespoke decentralised chemical manufacture model have been able to bring to market successful alternatives to high carbon use and high energy use manufacturing. Grenof have enabled decentralised and regionalised chemical manufacturing lowering carbon emissions and using waste products ad renewable energy sources. Renewable energy sources used in the Green Manufacturing Hubs includes gas from treatment plants and before the metre renewable energy sources allowing for sustainable and renewable manufacturing.

By having decentralised models allows for a spread of usage and off grid capabilities not available in centralised locations. Further sources of alternative energies are not centralised, and the Green Manufacturing Hub model allows for multiple chemicals to be manufactured in multiple locations using renewable energy and recycled waste sources, with no by-products unable to be used in the hubs.

As part of the Green Manufacturing Hubs, Grenof will manage the process from planning to souring and commissioning ensuring all renewable sources are included in the project. Grenof can manage the full process to ensure renewable and alternate sources of energy are included in all projects.

The Issue

- Australia currently has only one supplier of chlorine gas in Australia (Melbourne) and centralised liquid chlorine manufacturing plants in major cities.

- There is currently no calcium hypochlorite (powder, tablet, and granular chlorine) manufacturing in Australia.

- Chlorine Products are imported from China and chlorine Gas imported from Malaysia in large quantities.

- Products such as calcium hypochlorite, Aluminium chlorohydrate and Poly-aluminium chloride which are used extensively for municipal water treatment have unsecured supply chains, resulting in recent national stock outages across Australia.

- Covid pandemic issues and major weather events have been the cause of major disruptions to the normal supply chain of chemicals that are critical for water and wastewater treatment, sanitization, swimming pool maintenance and cleaning.

- Regional areas pay a premium for these chemicals (logistics costs, lack of competition and controlled / constrained supply).

- End users have resorted to stockpiling of chemicals causing degradation issues and adding further costs in their process.

- Cost escalations in Australia are compounded by increasing costs of imports and lack of local manufacturing.

- The Old-fashioned centralised models mean higher carbon footprints and increased costs.

The Solution

Regional Green Manufacturing hubs to enable:

- Localised employment

- Safe and sustainable chemical production.

- Balanced and fair pricing for all areas including regional and remote Australia.

- Significantly reduced supply chain risks.

Green Manufacturing Hubs are:

- Proven reliable technology.

- lowers sovereign risk and dependency on imported chemicals and materials.

- Strategically linked, decentralised green manufacturing hubs where multiple critical chemicals can be manufactured in the one location and distributed locally.

- Starting with chlorine production (used for other chemical production such as ACH, PAC, and HCL).

- Hubs utilise Australian raw materials and focus on renewable energy and local material sourcing.

- Empowers regional supply chains supporting local business and lowers carbon emissions and provides greater security of supply.

- Boosts sustainable localised employment through construction, operation, maintenance, packaging, logistics directly with indirect logistics, support services, chemical blending and manufacturing.

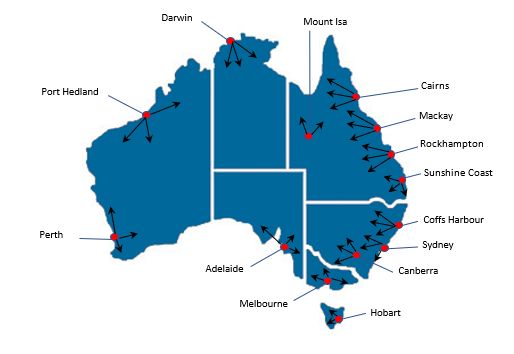

- Focuses on chlorine production in all forms and build upon this capability in stages ensuring success short and long term. Proposed hubs are below.

The Benefits

- Decrease and even exclude the need to import products that are becoming difficult to import.

- Lower Australian Sovereign risk and reliance on imports for our most important chemicals used here in Australia across large industry spectrums.

- Enable security of supply and lower supply chain vulnerabilities by having multiple plants strategically placed around Australia.

- Decentralise manufacturing and regionalise the process to enable for localised employment, increase sustainability, standardise pricing for metropolitan and regional areas.

- Set up linked decentralised Green Manufacturing Hubs where multiple highly important chemicals can be manufactured in the one collation and linked together so raw materials produced can be used for other manufacturing.

- Sustainable approaches to manufacturing by lowering carbon footprints, by products and using renewable energy and waste products.

- Low-cost manufacturing hubs ensuring financial sustainability short and long term.

- Supporting a local Australian business who supports other Australian Businesses.